What are the properties of PAI material?

January 21, 2025

Is PC material good?

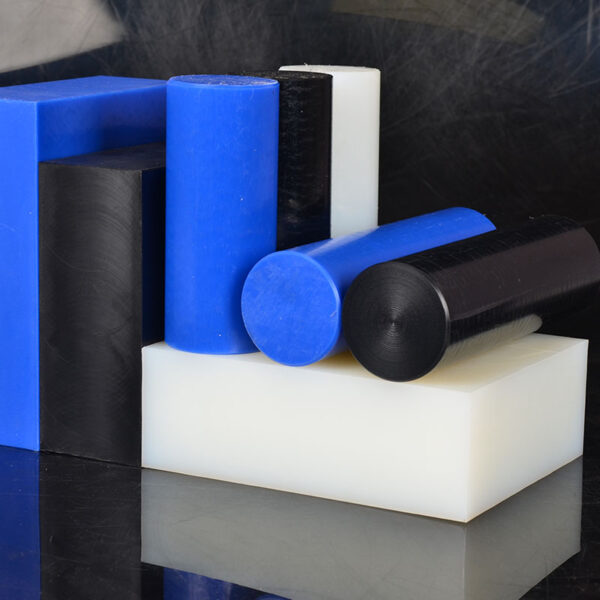

January 22, 2025PA (Polyamide) plastic, commonly known as nylon, is a versatile material used in a wide range of applications due to its excellent mechanical properties, durability, and resistance to wear and chemicals. The use of PA plastic spans various industries, from automotive to textiles, electronics, and beyond.

What is PA Plastic Used for in the Automotive Industry?

In the automotive industry, PA plastic is commonly used for manufacturing components such as fuel tanks, air intake manifolds, and under-the-hood parts. Its high strength, low friction, and resistance to high temperatures make it ideal for these applications. PA plastic helps reduce the weight of vehicles, improving fuel efficiency while maintaining durability.

What is PA Plastic Used for in Textiles?

In textiles, PA plastic is used to create fabrics such as nylon, which is highly durable, lightweight, and resistant to abrasion. Nylon fabrics are widely used in clothing, upholstery, ropes, and outdoor gear like tents and backpacks. PA plastic’s ability to be easily dyed and its resilience to wear make it a preferred choice for these products.

What is PA Plastic Used for in Electronics?

PA plastic also finds its application in the electronics industry. It is used to produce insulating materials for wires, connectors, and circuit boards. Its excellent electrical insulating properties and resistance to high temperatures make it suitable for electronic components that need to endure harsh environments.

What is PA Plastic Used for in Medical Devices?

In the medical field, PA plastic is used for manufacturing surgical instruments, implantable devices, and diagnostic equipment. Its biocompatibility, strength, and chemical resistance ensure the safety and longevity of medical tools and devices.

What is PA Plastic Used for in Industrial Applications?

PA plastic is frequently used in industrial applications such as bearings, gears, and conveyor components. Its low friction, wear resistance, and ability to operate in demanding environments make it ideal for machinery parts that undergo constant movement.