What are the applications of PE plastic?

January 23, 2025

Is POM plastic biodegradable?

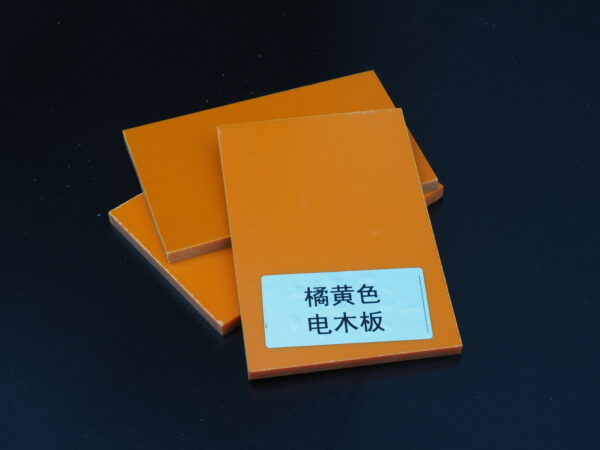

January 23, 2025In the early 20th century, the advent of Bakelite marked a revolutionary step in the world of synthetic materials. As the first true plastic, Bakelite transformed various industries with its unique properties, particularly its excellent electrical insulation abilities. Today, one of the most common and enduring uses of Bakelite remains in the realm of electrical insulators.

The Birth of Bakelite

Invented in 1907 by Belgian chemist Leo Baekeland, Bakelite was the result of a quest to find a synthetic substitute for shellac, a natural electrical insulator. Baekeland’s creation was the first entirely synthetic thermosetting plastic, meaning it could be molded into shape and then set through a heating process, retaining its shape even under high temperatures. This made it an ideal candidate for a variety of applications where stability and durability were crucial.

Electrical Insulation: A Primary Use

Bakelite’s primary advantage lies in its excellent insulating properties. It does not conduct electricity, which makes it invaluable in electrical and electronic applications. This non-conductivity, combined with its heat-resistant properties, ensures safety and reliability when used as an insulator.

Applications in Electrical Components

1. Switches and Sockets: One of the most ubiquitous uses of Bakelite is in electrical switches and wall sockets. Its insulating properties ensure that electrical currents are safely contained, reducing the risk of electric shocks and short circuits.

2. Components in Radios and Telephones: During its early years, Bakelite was extensively used in the manufacturing of radios and telephones. Its ability to withstand heat and not conduct electricity made it the perfect material for protecting delicate internal components.

3. Automotive Industry: In automobiles, Bakelite has been used for battery casings and various electrical parts, ensuring stability and durability even in demanding conditions.

Why Bakelite Stands Out

The reason Bakelite has been so successful in these applications is its combination of physical properties. It is resistant to heat, water, and many chemicals, ensuring longevity and performance consistency. Moreover, its ease of molding allows for the production of complex shapes and detailed designs needed for various electrical components.

Conclusion

While newer materials have emerged over the years, Bakelite’s role as a reliable electrical insulator remains significant. Its continued use in certain sectors is a testament to its unique properties and the foresight of its inventor, Leo Baekeland. As technology advances, Bakelite serves as a reminder of the enduring impact of early 20th-century innovations on modern industry.

In a world increasingly dependent on electricity and electronic devices, the importance of safe and effective insulation cannot be overstated. Bakelite, with its remarkable insulating properties, continues to be a material of choice, ensuring safety and efficiency in electrical applications across the globe.