What Are PVDF Rods?

-

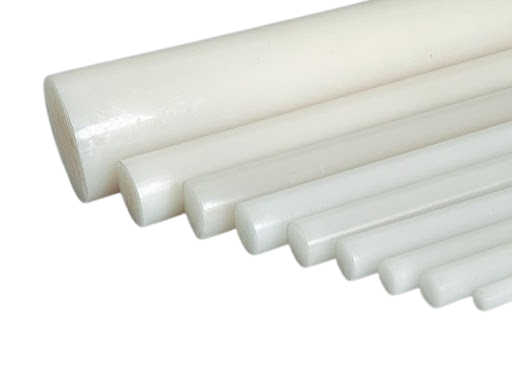

- Solid rods made from Polyvinylidene Fluoride (PVDF)

- High-performance fluoropolymer known for its robustness

- Used in various industrial and high-tech applications

-

Historical Background

- Developed in the 1960s for its superior chemical and thermal properties

- Initially used in chemical and aerospace industries

Processing and Fabrication

-

Machining

- Cutting: Can be cut to size using standard cutting tools

- Drilling and Turning: Precision drilling and turning are achievable

-

Custom Fabrication

- Custom Sizes: Can be fabricated into various sizes and shapes

- Tolerances: High precision tolerances can be maintained

Properties of PVDF Rods

-

Physical Properties

- Color: Typically white or translucent

- Density: Approximately 1.78 g/cm³

- Rigidity: High rigidity and dimensional stability

-

Thermal Properties

- Service Temperature: Effective up to 150°C

- Thermal Conductivity: Low thermal conductivity, useful for insulation

-

Chemical Resistance

- Acids and Bases: Excellent resistance to most acids and bases

- Solvents: Highly resistant to organic solvents and chemicals.

Applications of PVDF Rods

-

Chemical Processing

- Piping and Tubing: Used in piping systems for handling corrosive chemicals

- Valve Components: Ideal for valve seats and seals due to chemical resistance

-

Aerospace Industry

- Structural Components: Employed in aerospace components for its lightweight and durable properties

- Insulation: Used for insulating cables and other sensitive components

-

Medical and Pharmaceutical

- Processing Equipment: Components for pharmaceutical and laboratory equipment

- Diagnostic Devices: Parts for diagnostic and medical devices.

Safety and Handling

-

Storage

- Conditions: Store in a cool, dry place away from direct sunlight

- Protection: Protect from extreme temperatures and physical damage

-

Handling Precautions

- Protective Gear: Use appropriate protective gear when handling

- Ventilation: Ensure proper ventilation during machining

-

Disposal

- Regulations: Follow local regulations for disposal

- Recycling: Explore recycling options for PVDF materials

Advantages of PVDF Rods

-

Durability

- Long Lifespan: Resilient in harsh environments, long-lasting

- Low Maintenance: Requires minimal maintenance

-

Non-Reactivity

- Chemical Safety: Safe for use with a wide range of chemicals

- Stable Performance: Maintains performance in extreme conditions

Limitations of PVDF Rods

-

Cost

- Material Costs: Generally higher cost compared to some alternative materials

- Processing Expenses: Requires specialized equipment for precise fabrication

-

Flexibility

- Limited Flexibility: Can be less flexible compared to other materials, may be prone to cracking under certain conditions

Future Trends

-

Research and Development

- Enhanced Properties: Ongoing research to improve flexibility and impact resistance

- Cost Reduction: Innovations aimed at reducing material and production costs

-

Emerging Applications

- Innovative Uses: Potential for new applications in emerging technologies

- Sustainable Practices: Development of more environmentally friendly processing methods