What are the properties of polyvinyl fluoride?

January 13, 2025

Is PAI a thermoplastic?

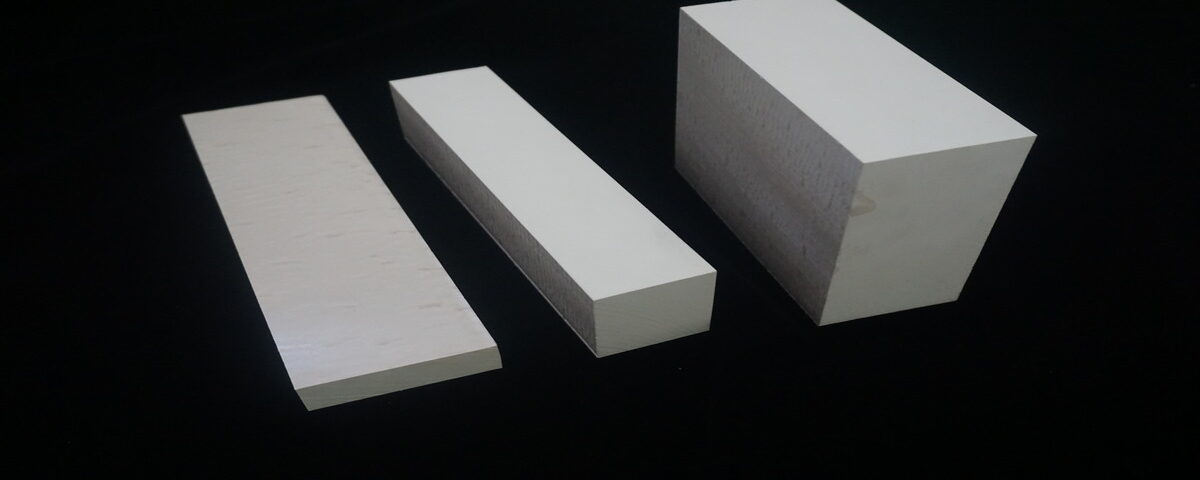

January 13, 2025A PPS (Polyphenylene Sulfide) sheet is a high-performance thermoplastic material known for its excellent chemical resistance, mechanical properties, and thermal stability. PPS sheets are used in a wide range of industries, including automotive, electronics, and manufacturing, due to their durability and reliability in harsh conditions.

1. Composition of PPS Sheet PPS sheets are made from polyphenylene sulfide, a polymer synthesized through a condensation reaction of aromatic compounds with sulfur. This material is characterized by its rigid, crystalline structure, which contributes to its high strength and resistance to heat and chemicals.

2. High Temperature Resistance One of the primary reasons PPS sheets are highly valued is their ability to withstand extreme temperatures. PPS can maintain its structural integrity in temperatures ranging from -50°C to +260°C, making it ideal for applications that require thermal stability, such as in automotive parts and industrial machinery.

3. Excellent Chemical Resistance PPS sheets offer exceptional resistance to a wide range of chemicals, including acids, bases, and solvents. This makes them suitable for use in aggressive environments, such as chemical processing plants, where other materials may degrade or corrode.

4. Low Creep and High Mechanical Strength PPS is known for its low creep, which means it maintains its shape and strength under continuous stress over time. It also possesses high tensile strength and resistance to wear and fatigue, making it ideal for use in high-load applications.

5. Electrical Insulating Properties PPS sheets exhibit good electrical insulating properties, making them useful in electronic and electrical applications where reliable insulation is required, such as circuit boards and connectors.

In conclusion, PPS sheets are valued for their high temperature resistance, chemical resistance, mechanical strength, and electrical insulating properties, making them a versatile material for demanding applications.