Why is PCTFE So Expensive?

December 10, 2024

What is HDPE Sheets Used For?

December 11, 2024CNC machining involves using computer-controlled tools to cut, shape, and fabricate materials with high precision. When selecting a plastic for CNC machining, several factors, such as durability, strength, ease of machining, and application requirements, should be considered. Below are some of the best plastics commonly used in CNC machining.

1. Acrylic (PMMA)

Acrylic, or polymethyl methacrylate (PMMA), is one of the best plastics for CNC machining due to its clarity, excellent surface finish, and ease of machining. It offers good impact resistance and is often used for creating clear, durable components such as display cases, lenses, and light fixtures. Acrylic machines well with minimal tool wear and produces smooth, high-quality surfaces.

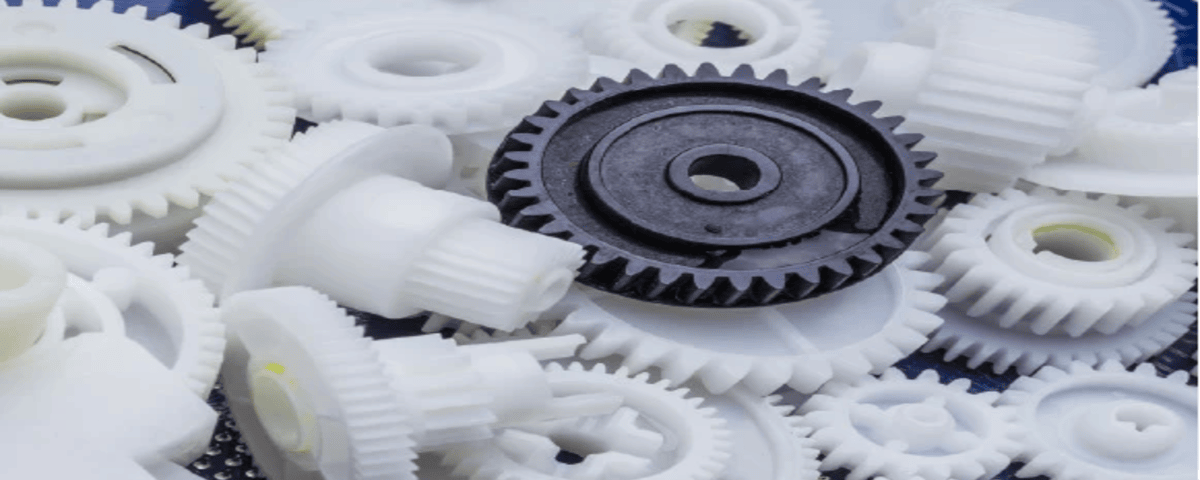

2. Nylon

Nylon is a versatile, durable plastic with excellent wear resistance, low friction properties, and high strength. It is frequently used in CNC machining for creating gears, bearings, and other mechanical components. Nylon’s ability to absorb moisture can affect its dimensions, so it’s important to account for this factor during machining. Despite this, nylon’s overall performance makes it an excellent choice for many industrial applications.

3. Polycarbonate (PC)

Polycarbonate is known for its high impact resistance, transparency, and dimensional stability, making it an ideal material for CNC machining when strength and durability are required. It is commonly used for creating tough, transparent parts such as protective covers, windows, and housings. Polycarbonate can be challenging to machine due to its tendency to deform under high heat, but with the right tools and techniques, it can be processed effectively.

4. Delrin (Acetal)

Delrin, or acetal, is another excellent plastic for CNC machining, known for its strength, stiffness, and low friction properties. It is ideal for precision mechanical parts like gears, bushings, and bearings. Delrin machines easily and has a smooth finish, making it popular in industries that require high-performance, low-wear components.

5. PEEK (Polyetheretherketone)

PEEK is a high-performance thermoplastic known for its excellent chemical resistance, thermal stability, and strength at high temperatures. While it can be more expensive and challenging to machine than other plastics, PEEK is often used in aerospace, automotive, and medical industries for parts that need to withstand extreme conditions.

Conclusion

The best plastic for CNC machining depends on the specific application and performance requirements. Acrylic, nylon, polycarbonate, Delrin, and PEEK are all excellent choices, each offering unique benefits for various industries. The ideal plastic will balance ease of machining with the material properties needed for the final product.