Why is PVDF Used?

December 10, 2024

Why is PCTFE So Expensive?

December 10, 2024Polytetrafluoroethylene (PTFE) is a synthetic fluoropolymer used in various industrial applications due to its high resistance to heat, chemicals, and electrical conductivity. The process of manufacturing PTFE involves several steps, with the key method being polymerization of tetrafluoroethylene (TFE) monomers. Here’s an overview of the manufacturing process:

1. Polymerization of Tetrafluoroethylene (TFE)

The first step in PTFE manufacturing is the polymerization of tetrafluoroethylene (TFE) monomers. TFE is a gaseous compound, and to initiate polymerization, it is typically subjected to high-pressure reactors in the presence of an initiator like organic peroxides. The process leads to the formation of long chains of PTFE molecules, creating a white, waxy solid.

2. Suspension Polymerization

In the suspension polymerization process, TFE is introduced into a water-based system where it is suspended in small droplets. The polymerization occurs when TFE molecules react with the initiator, producing PTFE particles. The water helps control the temperature and prevents the formation of lumps. This process results in the production of fine PTFE powders.

3. Milling and Processing

Once the PTFE polymer is synthesized, it is processed by milling to reduce particle size. The resulting PTFE powder is then shaped into various forms, including fine powders, granules, or fine particles. Depending on the final use, the powder can undergo different treatments.

4. Extrusion or Molding

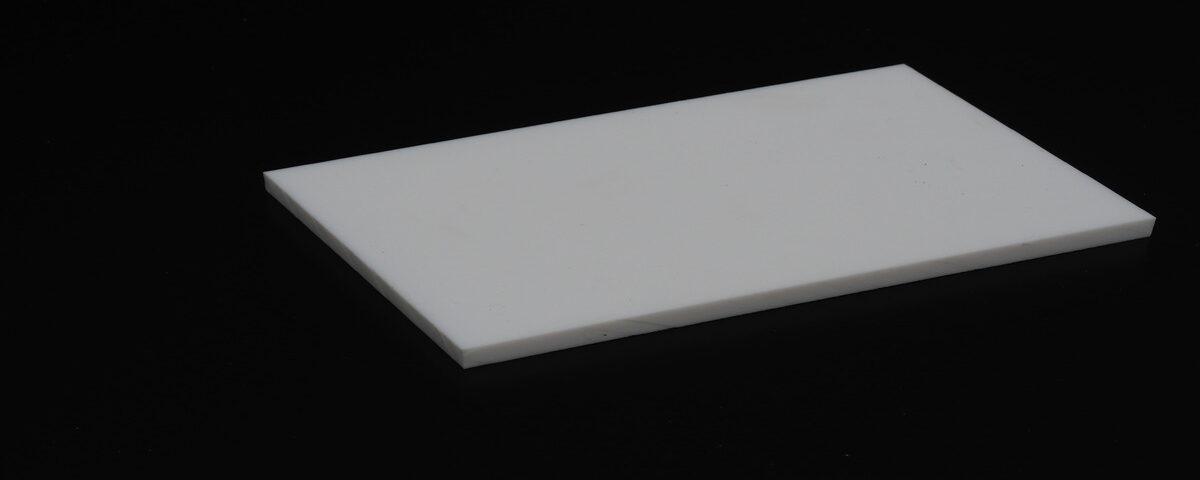

The PTFE powder is combined with lubricants or other additives to facilitate molding or extrusion. During extrusion, the material is forced through a mold to form products such as rods, sheets, or films. Alternatively, molding can produce complex shapes.

5. Sintering

After extrusion or molding, PTFE products undergo sintering, a heat treatment process that enhances the material’s mechanical properties. Sintering involves heating the PTFE parts to a high temperature, typically between 340°C and 380°C, causing the material to bond and form a solid, durable product.

Conclusion

Manufacturing PTFE involves careful control of the polymerization process, followed by milling, molding, and sintering. The result is a high-performance material with excellent chemical resistance, high thermal stability, and non-stick properties, ideal for diverse industrial applications.