What is PVDF Coating Used For?

December 2, 2024

What is the Difference Between PA6 and PP?

December 2, 2024Polytetrafluoroethylene (PTFE) is a high-performance fluoropolymer known for its exceptional properties, including chemical resistance, low friction, and high thermal stability. It is commonly referred to by its brand name, Teflon, and is widely used in industries ranging from aerospace to consumer products. PTFE’s unique characteristics make it ideal for a variety of applications that require durability and resistance to extreme conditions.

Non-Stick Cookware

One of the most common uses of PTFE is in non-stick cookware. Due to its low friction properties, PTFE prevents food from sticking to the surface, making cooking and cleaning easier. It is most often found as a coating on frying pans, baking trays, and other kitchenware, ensuring food is cooked without excessive oil or butter.

Electrical Insulation

PTFE is widely used as an insulating material in the electrical industry. It is an excellent insulator due to its high dielectric strength and resistance to heat, chemicals, and electrical conductivity. PTFE-coated wires and cables are commonly used in telecommunications, power transmission, and electronics, where reliable performance under extreme conditions is required.

Gaskets and Seals

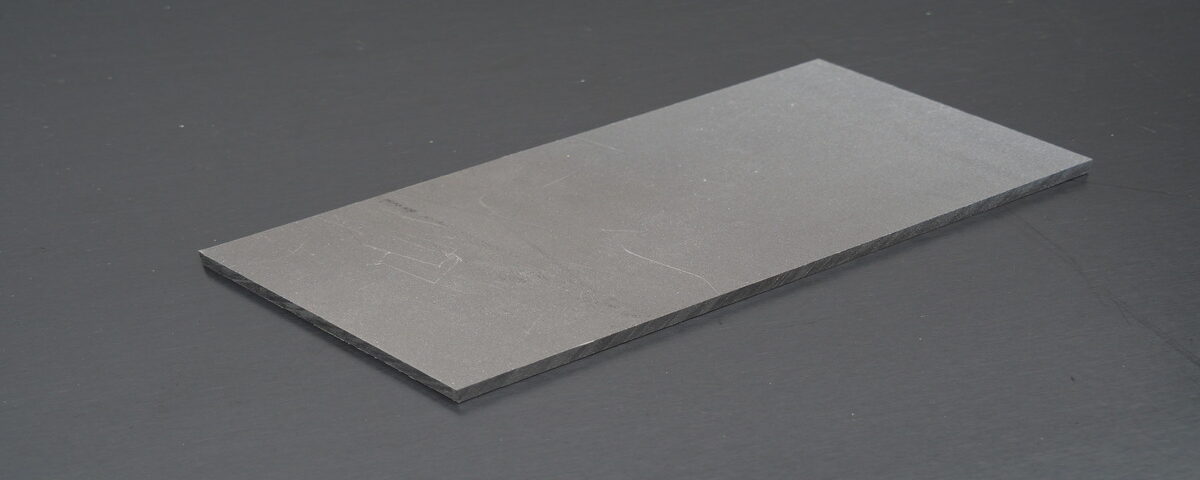

In industrial settings, PTFE is used to manufacture gaskets, seals, and washers. These components are essential in preventing leaks and maintaining airtight or watertight seals in pumps, valves, and other machinery. PTFE’s resistance to chemicals and high temperatures makes it particularly useful in the chemical processing, oil, and gas industries.

Lubrication and Bearings

Due to its low friction properties, PTFE is also used in lubrication applications. It is commonly applied in bearings, bushings, and sliding components, reducing wear and tear in mechanical systems, which improves performance and extends the lifespan of machinery.